The glass industry continues to evolve every year, and manufacturing companies today require accurate, polished, and aesthetically appealing glass surfaces for their products. Whether used for windows, architectural installations, furniture, interior design, or industrial applications, edges play an essential role in enhancing both safety and appearance. This is where a Glass Edging Machine becomes an indispensable asset. These machines help manufacturers deliver smooth, refined, and durable edges while improving production speed and quality. With rising competition in the global glass marketplace, businesses are looking for equipment that not only delivers precision but also ensures cost-efficiency and consistency over long production cycles.

In the United States, Ervin Sales Group USA has emerged as one of the most trusted suppliers of advanced Glass Edging Machines for large-scale factories and mid-size manufacturing units. Known for their cutting-edge technology and industry-ready design, the equipment supplied by the brand supports multiple edge-types, glass thickness variations, and custom production workflows. Over the years, the demand for better surface finishing has increased significantly because the market now values ultra-polished and safe glass products for interior and exterior use. Businesses that invest in high-performance edging solutions gain a competitive advantage in terms of quality output, safety compliance, and optimized operational costs.

What is a Glass Edging Machine? – A Deep Understanding

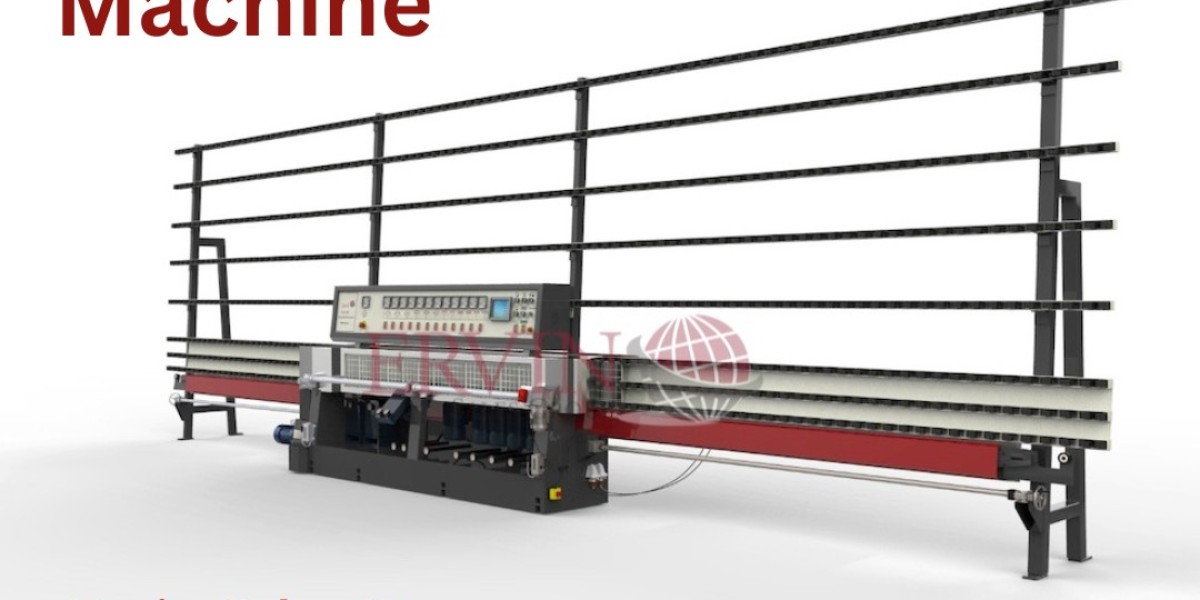

A Glass Edging Machine is a specialized industrial solution engineered to smooth, shape, and polish the edges of glass sheets after cutting. The sharpening and polishing of the glass edge ensure that the final product not only looks visually appealing but also supports enhanced safety by eliminating sharp and breakable corners. These machines operate through high-precision grinding wheels or belts that remove unevenness and refine the glass to the required finish. Depending on the design of the machinery, the system can create different profiles like flat edges, OG edges, pencil round edges, and bevel finishes, catering to multiple industry needs.

The demand for standardized and quality-driven edging has significantly grown because raw glass cutting is never perfectly smooth and tends to leave sharp, dangerous fragments. Without proper edge finishing, the glass becomes prone to cracks and breakage, compromising user safety and structural reliability. A modern Glass Edging Machine resolves these issues by maintaining consistent pressure and grinding accuracy throughout the entire processing stage. Additionally, advanced systems now feature automated controls, digital calibration, and multi-wheel configurations, enabling factories to produce high-volume outputs without compromising precision.

Why Edging Matters in Today’s Glass Manufacturing Industry

While many people associate edging simply with appearance, it actually contributes to multiple industrial advantages. First, the structural strength of the glass significantly increases when edges are polished and correctly shaped. The risk of cracks spreading due to stress points gets reduced tremendously once the sharpness of the edges is eliminated. From a safety standpoint, polished glass is essential for residential and commercial installations, especially for items exposed to physical interaction, such as doors, table tops, shower partitions, and railing panels.

Aesthetic value is another vital aspect of edging. With increased demand for interior décor and modern architectural elements, design experts and homeowners prefer seamless and glossy edges that enhance the premium look of glass furniture and fixtures. Companies using a Glass Edging Machine can produce highly attractive finishes that elevate the perceived value of their products. Furthermore, in high-temperature and toughened glass applications, edge processing prevents stress concentration during the tempering phase, ensuring an even heat distribution and better durability of the final product.

Ervin Sales Group USA – Delivering Technology-Driven Glass Edging Solutions

Ervin Sales Group USA is widely recognized for supplying industry-leading Glass Edging Machines that combine speed, accuracy, and reliability. Their machinery is designed to meet the evolving needs of manufacturers who demand high output without compromising quality. With a deep understanding of the U.S. glass production market, the company focuses on providing durable machines that offer long-term operational value, reduced maintenance needs, and user-friendly integration into modern production lines. Whether a glass factory handles small custom projects or large industrial contracts, Ervin Sales Group USA offers scalable solutions for both.

The brand stands out due to its commitment to after-sales service and customer assistance. For many factories, investing in a machine is only the first step; what matters most is ongoing support, spare parts availability, and professional installation assistance. Ervin Sales Group USA ensures that clients have access to total operational guidance so that machines are always running at optimal performance. Their equipment lineup is tailored to various manufacturing levels—from manual edging units to full CNC-controlled edging systems—allowing businesses to upgrade production capacity according to their requirements.

Types of Glass Edging Machines Available in the Market

Understanding the different categories of edging machines helps businesses choose a model suited to their application. Below are the major types commonly adopted in the glass manufacturing sector:

? Straight Line Glass Edging Machines

These machines focus on processing flat glass panels in a straight line while producing polished or ground edges. They are the most widely used machines due to their speed and versatility, especially for commercial and industrial-scale glass production.

? Double Edging Machines

Ideal for high-volume facilities, double edging machines polish two opposite edges simultaneously. This reduces the processing time and allows factories to achieve a high throughput rate. They are extremely useful in applications like glass furniture, windows, and automotive manufacturing.

? Shape Edging and Beveling Machines

These machines are specialized for designing edges in various shapes and angles, especially for artistic, luxury, or interior décor applications. They can handle circular, oval, or irregular-shaped glass pieces while providing high-precision polishing.

By choosing the correct Glass Edging Machine, factories can streamline their workflow and achieve higher productivity without increasing labor effort. Different forms of automation, wheel types, and control panels allow businesses to select options based on their production goals.

Benefits of Investing in a High-Quality Glass Edging Machine

A modern edging system enables glass manufacturers to optimize both quality and performance across their production cycles. Some of the biggest advantages include improved product durability, reduced safety hazards, and increased visual appeal. Investing in a Glass Edging Machine minimizes manual labor requirements while delivering consistent and repeatable finishing results. For businesses that handle bulk orders, automation capabilities significantly reduce human error and ensure a faster turnaround.

Another major benefit is the cost savings achieved in the long run. While the upfront investment in high-grade machinery may seem high, the overall profitability increases through material wastage reduction and higher-quality output. Polished and smooth edges prevent breakage during transport and installation, reducing replacement costs. Furthermore, satisfying customers with refined and high-end finishing results enhances brand reputation and opens doors to premium pricing opportunities.

Industries That Rely Heavily on Glass Edging Machines

Various industries integrate edging technologies into their manufacturing because polished glass edges improve both functionality and visual presentation. Residential and commercial interior design companies depend on edging for designer tables, kitchen countertops, wardrobes, shower panels, and decorative partitions. The building and construction sector demands edging for windows, façades, doors, and structural glass installations. Beyond architecture, automotive manufacturers also use polished glass for windshields, sunroofs, and mirror assemblies, contributing to vehicle safety standards.

The electronics and display industry is another major buyer of edging equipment, particularly for LCD panels, smart home screens, and premium glass casings. Even artistic and handcrafted glass studios rely on edging for high-finish craft and decorative pieces. The global shift toward glass-based products has amplified the role of machinery that supports accuracy and aesthetic finesse.

Why Choose Ervin Sales Group USA for Glass Edging Machines?

Glass factories across the USA trust Ervin Sales Group USA due to their consistency in supplying high-performance machines from globally renowned manufacturers. Their priority is to offer equipment with long service life, fast processing capability, and robust quality control mechanisms. Each Glass Edging Machine provided by the company undergoes heavy-duty testing to ensure that it meets the requirements of industrial applications.

Moreover, the brand delivers excellent technical support, installation assistance, on-site training, and replacement parts. Whether a new glass plant is being set up or an existing facility is upgrading machinery, Ervin Sales Group USA provides expert guidance based on production scale and financial planning. The company believes in building long-term partnerships where customers benefit from operational efficiency and machine sustainability.

Conclusion – A Smart Investment for Future-Ready Glass Manufacturing

As the demand for premium-quality glass continues to rise across residential, commercial, automotive, and industrial sectors, installing a Glass Edging Machine has become a necessity rather than a luxury. Businesses focused on long-term growth must adopt advanced edging solutions to deliver polished, durable, and visually appealing glass products. Partnering with trusted suppliers like Ervin Sales Group USA ensures that glass factories not only achieve competitive output but also maintain continuous production with reduced operational downtime.

Choosing a high-performance edging solution today means securing improved production quality, customer satisfaction, and profitability tomorrow. Any glass manufacturer looking to upgrade their workflow, reduce material waste, and increase safety should consider the long-term value and ROI offered by a durable and technologically advanced glass edging system.

Frequently Asked Questions (FAQs)

1. What is a Glass Edging Machine used for?

A Glass Edging Machine is used to polish, smooth, and shape the edges of glass sheets to make them safe, durable, and visually appealing. It removes sharpness and irregularities left after cutting and prepares the glass for commercial, architectural, and decorative applications.

2. Which industries commonly use Glass Edging Machines?

Industries such as interior design, construction, automotive manufacturing, architectural glass production, furniture, and electronics are major users of Glass Edging Machines due to the need for polished and safe glass surfaces.

3. How do Glass Edging Machines improve product quality?

They enhance product quality by eliminating cracks and sharp corners, reducing breakage during handling, and creating sleek and professional finishes. This improves both safety and aesthetics while increasing product value.

4. Are automated edging machines better for large factories?

Yes, automated systems are ideal for large-scale facilities because they ensure consistent polishing, fast volume production, reduced labor requirements, and higher precision even in continuous operations.

5. Why choose Ervin Sales Group USA for Glass Edging Machines?

Ervin Sales Group USA provides efficient, durable, and high-performance edging machines along with professional installation support, after-sales service, and expert guidance. Their solutions ensure long-term value and optimized production output.

Contact:

ERVIN, Inc.

13116 Lincoln Way #3138

Auburn, CA 95604

Ph: 9169338367

Email: sales@ervinsales.com

Visit now: https://www.ervinsales.com/glass-machinery-products/10-Spindle-Glass-Edging-Machine.html