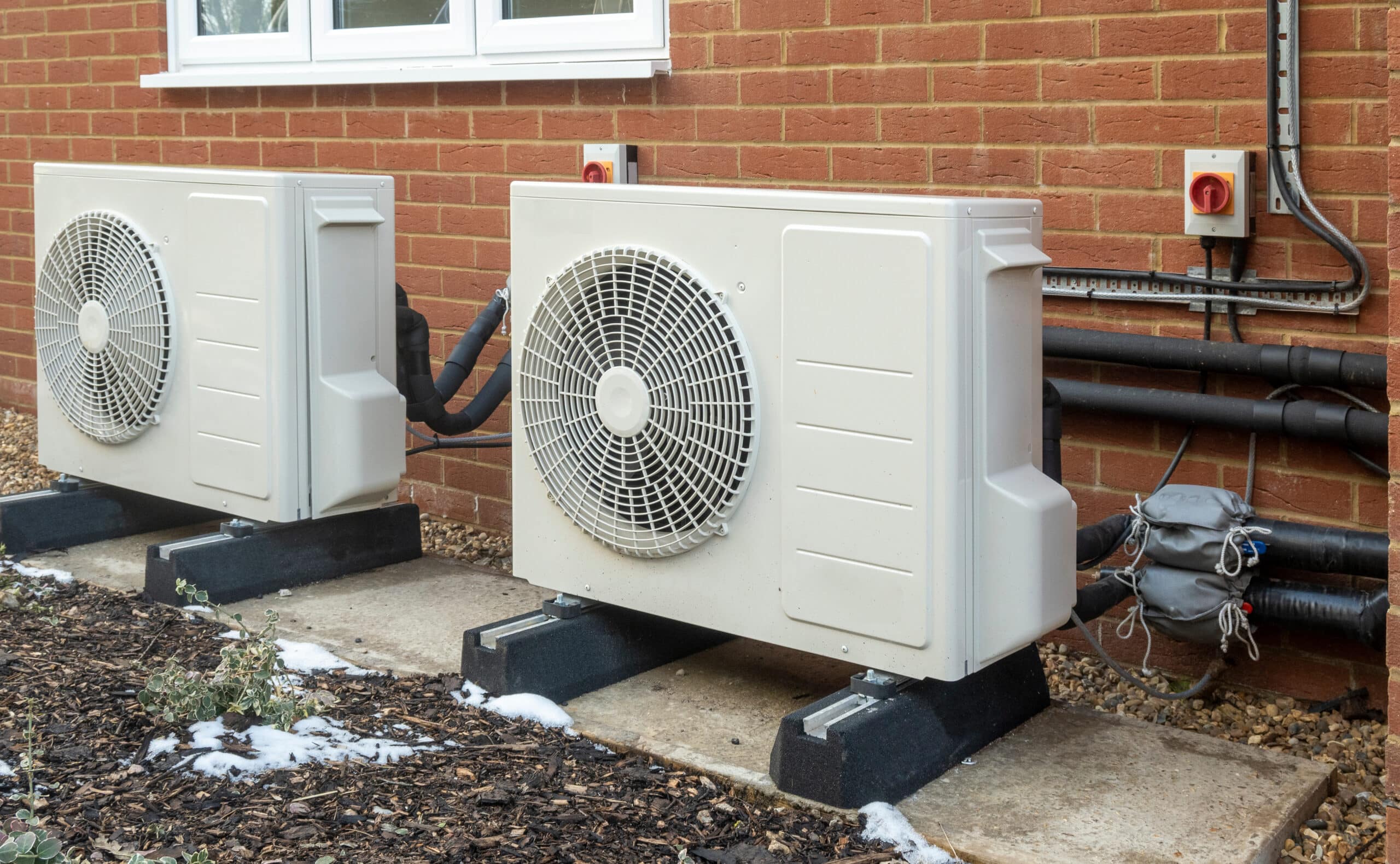

Reliability and safety drive every good cooling decision, especially when the forecast spikes and systems run hard. Knowing the steps ahead helps you stay calm and in control. We’ll walk through scoping, parts, timing, risk, and maintenance so your choices feel solid. For local homes and light commercial spaces, details matter more than buzzwords. Follow steady, proven steps, and you’ll sidestep most hot-day breakdowns. We center on safety and reliability at every stage. If you need fast help, air conditioning repair lake charles la should fit into a clear plan, not guesswork. You’ll learn easy cues that signal action now. With sensible scheduling and the right HVAC checks, you can protect comfort, curb costs, and avoid needless downtime.

Clarify needs early to guide each repair step

Start with a walkthrough that lists symptoms, unit age, warranty status, and access limits. You can begin with ac repair lake charles to review availability and timing. Create a short brief that notes thermostat behavior, breaker trips, and any ice on the line set. Include attic or closet access notes to prevent delays. A simple scope sheet prevents rework and missed parts.

Lay out steps from check-in to final test. Agree who approves parts above a threshold. Confirm power shutoff locations so the tech can work safely. Name a backup decision maker for fast choices. These small steps keep the visit predictable.

Align replacements with specs and lifespan goals

List needed parts after testing: capacitors, contactors, fan motors, or refrigerant by type and charge. Your next step can include ac repair lake charles to confirm stock windows and lead times. Select OEM or proven equivalents where it truly matters, like control boards. For filters, size properly and note MERV to protect airflow. Well-matched components curb failures later.

Record static pressure, temperature split, and amp draw before and after the fix. Document readings in the work order so future visits have context. If duct leaks show up on smoke tests, plan a sealant step or a follow-up. Those numbers make budget decisions easier. Data makes guesswork vanish.

Stagger tasks to limit downtime and delays

Set your window when the building is coolest to reduce stress on the system. You might start by using ac repair lake charles to pick a time slot that fits. Stage steps: diagnose first, approve parts, then repair and test performance under load. When coils are iced, schedule a quick return to finish measurements. Good timing preserves comfort.

For urgent homes, search ac repair near me to find a team with fast dispatch. Request ETA texts and milestone notes. Keep pets secured and clear five feet around the condenser for quick access. Confirm parking or loading spots. Smooth flow beats last-minute scrambles.

Make reliability measurable with targeted controls

Use a two-pass test: first safety, then performance. You can quickly add ac repair lake charles to line up a follow-up verification if needed. Safety looks for arcing, brittle wires, loose lugs, and proper disconnect labels. Performance checks confirm superheat or subcool, correct fan rotation, and drain slope. These basics block most repeat calls.

Add photos of meter readings and label them by step. Photos document context and choices that matter. When numbers drift after ten minutes, recheck airflow and charge before closing out. Five minutes of retesting beats a return trip. Reliability is built in small confirmations.

Protect comfort using seasonal tune-ups

Schedule seasonal cleanings, drain flushes, and coil rinses based on local dust and pollen. A direct path is to use Ac Repair Lake Charles and set a recurring service. Calibrate thermostats, tighten lugs, and replace UV lamps only by hour rating. Check surge protection on the condenser to guard boards during storms. Small habits lengthen service life.

For mixed-use spaces, log monthly filter changes and quarterly checks. Tie maintenance to warranty terms so coverage stays intact. If deeper issues arise, the HVAC team can phase repairs to match budget cycles. That keeps operations smooth while costs stay predictable. Care today dodges breakdowns tomorrow.

Conclusion

Quality and risk management turn hot-day emergencies into plain, steady steps. We scoped needs early, matched parts to real data, and staged the day to cut downtime. Then we verified safety and performance before shifting into maintenance that builds long-term reliability with HVAC. Keep these habits close, and your comfort, costs, and system lifespan will all move in the right direction.