In today’s competitive glass fabrication industry, quality, efficiency, and consistency are non-negotiable. One critical piece of equipment that directly impacts the final quality of glass products is the glass washing machine. Whether you are preparing glass for cutting, drilling, tempering, or lamination, a reliable washing solution ensures spotless, residue-free surfaces that meet the highest industry standards.

At Ervin Sales Group USA, we specialize in supplying advanced glass machinery designed to help manufacturers, processors, and fabricators stay ahead of the curve. From high-performance glass washing machines to precision glass drilling machines and glass cutting machines, we deliver equipment that maximizes productivity while maintaining superior quality.

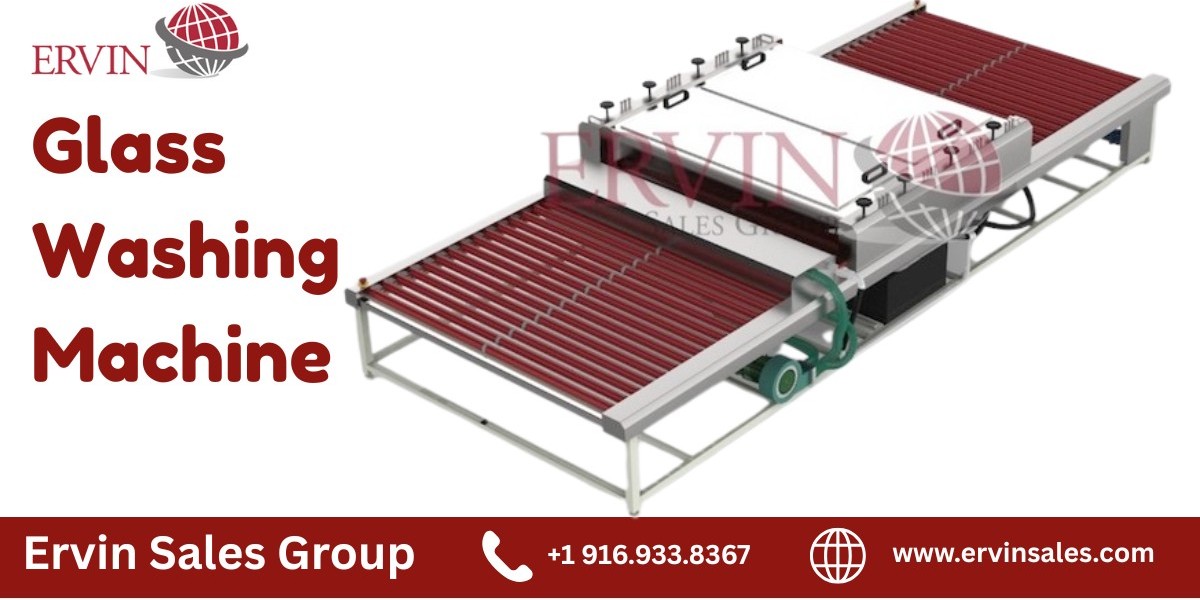

What Is a Glass Washing Machine?

A glass washing machine is an essential component in modern glass processing lines. It is designed to clean glass sheets thoroughly by removing dust, oil, residues, and contaminants after cutting, edging, drilling, or grinding processes.

Clean glass is crucial for:

- Accurate drilling and cutting

- Strong bonding in laminating processes

- Flawless tempering results

- Premium optical clarity in architectural and automotive glass

Without a proper glass washing system, even the most advanced glass cutting or drilling machines cannot deliver optimal results.

Why Glass Washing Machines Are Essential in Glass Processing

Glass processing involves multiple stages, and contamination can occur at any step. A high-quality glass washing machine ensures consistent results by:

1. Enhancing Final Glass Quality

Clean surfaces eliminate streaks, water spots, and residues, improving transparency and finish.

2. Improving Machine Performance

Clean glass reduces wear and tear on downstream equipment such as glass drilling machines and tempering furnaces.

3. Increasing Productivity

Automated washing systems minimize manual labor and reduce production downtime.

4. Meeting Industry Standards

Modern washing machines help meet stringent quality and safety requirements in architectural, automotive, and industrial glass applications.

Types of Glass Washing Machines Offered by Ervin Sales Group USA

As a trusted name in glass machinery, Ervin Sales Group USA offers advanced solutions tailored to various processing needs.

Horizontal Glass Washing Machines

Ideal for flat glass processing lines, these machines integrate seamlessly after a glass cutting machine or edging system.

Vertical Glass Washing Machines

Perfect for insulated glass (IG) and coated glass applications, offering excellent drying performance.

High-Speed Industrial Glass Washers

Designed for large-scale operations where throughput and consistency are critical.

Each glass washing machine we supply is engineered for durability, efficiency, and ease of maintenance.

Integration with Other Glass Machinery

A glass washing machine is most effective when paired with other precision equipment.

Glass Cutting Machine

After cutting, glass sheets often contain fine particles and residues. Washing ensures a clean surface before further processing.

Glass Drilling Machine

Drilling requires spotless glass to prevent cracks, tool damage, and alignment issues.

Complete Glass Machinery Line

From cutting and washing to drilling and finishing, Ervin Sales Group USA provides fully integrated glass machinery solutions that streamline operations and improve output quality.

Key Features of Modern Glass Washing Machines

When investing in a glass washing machine, consider features that enhance efficiency and performance:

- Multi-stage washing and rinsing systems

- High-efficiency air knife or blower drying

- Adjustable brush pressure for different glass thicknesses

- Stainless steel construction for corrosion resistance

- Energy-efficient motors and water recycling options

Our machines are designed to deliver consistent cleaning results while minimizing operating costs.

Why Choose Ervin Sales Group USA?

Ervin Sales Group USA is widely recognized as the best glass machinery supplier in USA, providing industry-leading equipment and customer support.

Industry Expertise

With decades of experience, we understand the real-world challenges faced by glass fabricators.

Premium Equipment

We supply reliable, high-performance glass washing machines, glass cutting machines, and glass drilling machines from trusted manufacturers.

Customized Solutions

Every glass operation is unique. We help you select machinery tailored to your production goals and budget.

Nationwide Support

From installation to after-sales service, our team supports customers across the United States.

Applications of Glass Washing Machines

A high-quality glass washing machine is essential across multiple industries:

- Architectural and façade glass

- Automotive glass manufacturing

- Furniture and interior glass

- Solar and specialty glass

- Insulated and laminated glass production

No matter the application, clean glass is the foundation of superior results.

Future Trends in Glass Machinery

As technology evolves, glass machinery continues to become smarter and more efficient. Modern glass washing machines are incorporating:

- Automation and smart controls

- Reduced water and energy consumption

- Enhanced drying technology

- Compatibility with high-speed production lines

Ervin Sales Group USA stays ahead of these trends, ensuring our customers always have access to cutting-edge solutions.

Frequently Asked Questions (FAQs)

1. Why is a glass washing machine important in glass processing?

A glass washing machine removes contaminants that can affect cutting, drilling, tempering, and finishing quality, ensuring flawless end products.

2. Can a glass washing machine be integrated with existing glass machinery?

Yes, most modern machines are designed to integrate seamlessly with glass cutting machines, glass drilling machines, and other glass machinery.

3. What industries use glass washing machines?

They are widely used in architectural, automotive, furniture, solar, and industrial glass manufacturing.

4. How do I choose the right glass washing machine?

Factors include glass size, thickness, production volume, and compatibility with existing equipment. Ervin Sales Group USA provides expert guidance.

5. Is Ervin Sales Group USA the best glass machinery supplier in USA?

Ervin Sales Group USA is trusted nationwide for high-quality equipment, expert support, and customized glass machinery solutions.

Call to Action – Partner with the Best in Glass Machinery

If you’re looking to upgrade your production line with a high-performance glass washing machine, or need complete solutions including glass drilling machines, glass cutting machines, and advanced glass machinery, Ervin Sales Group USA is your trusted partner.

? Visit Ervin Sales Group USA today to explore our full range of glass machinery and speak with our experts about the best solution for your business.

Visit: https://www.ervinsales.com/glass-machinery-products/Horizontal-glass-washing-machine-small.html